The specification of quality criteria which exceed those required by building regulations were first defined in 1995 in an agreement on KVH® structural timber, and have been continually updated ever since. To minimize cracking and deformation from shrinkage caused by drying, specifications for moisture content and the type of cutting were set down. Other criteria are concerned mainly with the dimensional stability and the appearance of the timber.

Grading criterion | Requirements for KVH® | Notes | |

|---|---|---|---|

Exposed areas | Non-exposed areas (KVH®-NSi) | ||

Strength class | C24, C24M | Other strength classes must be agreed upon separately (see table 1.2 of the agreements on construction timber) | |

Grading class in the case of a visual grading according to DIN 4074-1 | S10 | Other grading classes must be agreed upon separately (see table 1.2 of the agreements on construction timber) | |

Product standard | EN 14081-1 for non-finger-jointed KVH® structural timber |

| |

Moisture content | 15% ± 3% Kiln-dried: Wood that was dried to a moisture u of ≤ 20% in a controlled process in a suitable industrial plant at a temperature of T ≥ 55 °C for at least 48 hours. | The specified moisture content is a precondition for dispensing for the most part with preservative treatment, and can also be the precondition for finger joint assembly. | |

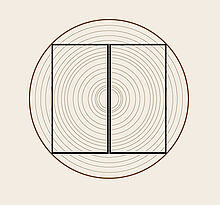

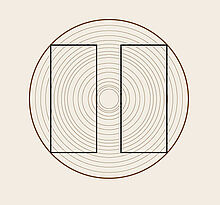

Type of cut | For a log with an ideal growth form, the pith is cut through in two-strand cutting. | For a log with an ideal growth form, the pith is cut through in two-strand cutting. |

|

Wane | not acceptable | ≤ 10% of the smaller cross-section side |

|

Dimensional stability | EN 336 Dimensional stability class 2: | The dimensional stability for the longitudinal dimensions must be agreed between the customer and the supplier. | |

Knot condition | Loose knots and dead knots not acceptable. Occasional faulty knots or parts of knots up to max. 20 mm in diameter are acceptable. | DIN 4074-1 |

|

Knots | S 10: A ≤ 2/5 | The following applies for mechanical grading: | |

Ingrown bark | not acceptable | DIN 4074-1 | Knot bark is added to the knot |

Cracks | Crack width b ≤ 3% | Crack width b ≤ 5% | Crack width b relating to the respective cross-section width |

Crack depth | Up to 1/2 |

| Measured according to DIN 4074-1 |

Pitch pockets | Width b ≤ 5 mm | - | Corresponds to DIN 68365 quality classes 1 and 2 |

Discoloration | not acceptable | Blue stains: acceptable | The requirements concerning KVH NSi correspond to those of grade S10 according to DIN 4074-1 |

Insect attack | not acceptable | Insect holes up to 2 mm diameter are acceptable | According to DIN 4074-1 |

Twisting | 1 mm per 25 mm height | Measured according to DIN 4074-1 | |

Longitudinal warping | ≤ 8 mm/2 m with removed heart plank ≤ 4 mm/2m | For split‐heart cut | Measured according to DIN 4074-1 |

Finishing of the ends | Trimmed perpendicular (by agreement) |

| |

Surface condition | Planed and chamfered | Levelled and chamfered |

|